A huge global effort by governments and corporations worldwide is going into the development of battery technologies, principally due to the accelerating demand for electric cars and an increasing need for energy storage systems both at the grid and household levels.

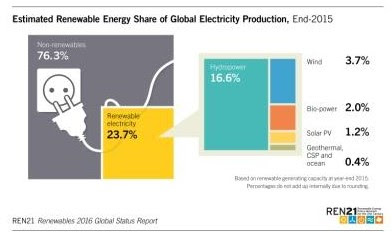

As the electricity network develops from one generated largely by fossil fuels into one with increasing levels of Renewable Energy, our supply will start to be affected by the unpredictable and intermittent behaviour of the sun and the wind. Also demand for electricity peaks in the morning and evening but solar energy peaks in the middle of the day. It is widely recognised that large-scale penetration of renewable energy can only be realised with the addition of electrical energy storage.

There is a lot of confusion and hype in the trade and mainstream media about "game-changing" battery technologies as companies and countries compete to capture a share of the action and investment in what promises to be major markets of the future.

So let's start with an article in Scientific American by Robert Fares [February 18, 2016] which highlights an excellent paper by Venkat Viswanathan and and his students at the Department of Mechanical Engineering at Carnegie Mellon University in the US. They were seeking to find a way to quantify the different kinds of battery chemistry and show where they were on the 'Hype Cycle'.

particular battery chemistry to determine its position...As you will see [above]: 'it ranges from the initial “innovation trigger” and “peak of inflated expectations” to the eventual “plateau of productivity,” where lithium-ion (Li-ion) batteries sit today.'

The other different classes of battery technologies on the chart are: Magnesium-ion (Mg-ion), sodium-ion (Na-ion), lithium-sulfur (Li-S). These all work in a similar fashion to Li-ion batteries but they are smaller, lighter and cost less.

As you cane see, the Li-is batteries are considered the most promising of these, having survived the “peak of inflated expectations” They are considerably cheaper because of the low cost of sulfur but there are still problems to solve.

The lithium-air (Li-air) batteries, which are further ahead, on the "slope of enlightenment", writes Fares, have 'enormous potential to beat out Li-ion because it uses a fundamentally different technique to store energy. The battery cell uses metallic lithium in its negative side and reacts with atmospheric oxygen on its positive side. Because one of the reactants in the battery is air, in theory you need half as much battery materials to store the same amount of energy, and the weight of the battery can be reduced by half.

This is especially appealing for electric vehicles, which would benefit greatly from smaller battery packs. However, Li-air batteries still have a long way to go before they can achieve the cost and lifetime of conventional Li-ion batteries....Li-ion is still the winning technology when it comes to portable electronics, electric vehicle, and grid applications.

Read the full academic paper: Oleg Sapunkov et al., 2015.

As you cane see, the Li-is batteries are considered the most promising of these, having survived the “peak of inflated expectations” They are considerably cheaper because of the low cost of sulfur but there are still problems to solve.

The lithium-air (Li-air) batteries, which are further ahead, on the "slope of enlightenment", writes Fares, have 'enormous potential to beat out Li-ion because it uses a fundamentally different technique to store energy. The battery cell uses metallic lithium in its negative side and reacts with atmospheric oxygen on its positive side. Because one of the reactants in the battery is air, in theory you need half as much battery materials to store the same amount of energy, and the weight of the battery can be reduced by half.

This is especially appealing for electric vehicles, which would benefit greatly from smaller battery packs. However, Li-air batteries still have a long way to go before they can achieve the cost and lifetime of conventional Li-ion batteries....Li-ion is still the winning technology when it comes to portable electronics, electric vehicle, and grid applications.

Read the full academic paper: Oleg Sapunkov et al., 2015.

*

THE ENERGY STORAGE INDUSTRY

|

| Alevo's "GridBank" units are shipping containers filled with lithium ferrophosphate and graphite batteries for energy storage. Each unit has 1MWh of storage |

'Cairn Energy Research Advisors (Cairn ERA) pays attention to the different ways storage might be applied, both today and in the future. The company tracks over 25 different applications, and for each of these has developed a separate business model. Managing Director Sam Jaffe says "If you were to own a battery, how would you make money operating that battery? Most of these models are not profitable today."

Batteries are much more complex than alternative energy systems. For a start you can 'absorb or release energy over specific time-frames in varying quantities. Jaffe observes that there are many things one can do with batteries and the use-cases vary from utility to utility, region to region, and country to country, and “nothing is simple about this industry".

Jaffe says that the use of chemical batteries for energy storage is 'still not quite ready for prime time widespread applications on the power grid' and that the thing that is holding it back is that batteries are still either too expensive, too weak in terms of capabilities or too fragile. 'They don’t last long enough to keep earning revenue long enough to pay off the loan.'

The good news is the emergence of lithium ion production at scale has helped solve the environmental issues previously related to lead acid batteries and costs have fallen to enable some initial grid applications.

A battery's lifetime is limited by the number of 'charge cycles' it can handle. In electric cars, the battery is only charging and discharging a few times in the week. The average vehicle sits idle for 93% of the time. So a battery that runs 300 cycles is affordable. Stationary storage applications for the grid require a much higher level of durability for heavy-duty cycle applications

'Costs continue to fall, and technologies advance, but no black swans on the immediate horizon: The good news is that analysts, including Jaffe, forecast a continued and consistent future price decline for installed storage...He’s confident that the power industry will figure out how to scale quickly and get storage costs down, just as the solar and wind industries have. Small and consistent steps lead to impressive gains over time... "You don’t notice it one year to the next," says Jaffe "but over five years they are extremely noticeable....in ten years there will be new chemistries that we will start to see commercialised."

Can flow batteries and other competing technologies ... grow to be giants? Jaffe thinks not, in large part because lithium ion enjoys economies of scale that will be hard for flow batteries to reach, at least in the near future.

"I think it’s safe to say we live in a lithium ion world and will continue to do so in the next ten years. However, there’s going to be a very large market for flow batteries...which will probably be able to occupy the niche that requires durability and a very large number of cycles – tens of thousands of cycles, compared with the five or six thousand lithium ion is currently good for. They will also fit into applications where many hours of storage are required. Vanadium flow batteries can last 10,000 cycles, but the price point is still out of reach. As the price comes down, that will definitely be one possibility.”

'In today’s market, storage plays in a few relatively constrained niches. These early beachheads include...firming up solar output in places like Germany, Australia, and Hawaii, supporting wind in Texas, and providing grid support in a (still) limited number of applications (the total deployed is less than a thousand megawatts worldwide). However, as costs fall, storage is will expand quickly into other areas.

'But Jaffe believes there is one area in the next decade where energy storage will be the killer app, and that is as a grid-scale dance partner to optimise gas-fired generation.

"The concept is you have a large combined cycle natural gas plant and a large battery next to it and you use batteries as buffer between grid demand and power plant capability. The concept is to use the batteries to meet fluctuating demand and buffer the combined cycle gas plant. That lets the generator run more efficiently at optimal heat rates most of the time, not ramping up or down."

Source: 'One Expert's View On The Near-Term Future Of Energy Storage' by Peter Kelly-Detwiler. (Forbes/June 6, 2016)

Recycled EV Batteries as a Storage System

'With increasing EV sales, some companies have looked at what to do with EV batteries once they have reached the end of their lives. Due to the metals in Li-ion batteries they cannot just be disposed of in landfill sites as they are hazardous and cause pollution. One option is to try and recycle the batteries by extracting the metals, such as lithium, cobalt, nickel and iron. However, it is currently not economical to do this as the cost to recycle lithium exceeds the cost of mining new lithium.

'Perhaps the most feasible idea for utilising old EV Li-ion batteries is to bundle them together and use them as electricity storage. Nissan is currently working with a company called Green Charge Networks to sell mass market energy storage systems using old Nissan Leaf batteries. General Motors (GM US) is also pursuing a similar plan using Chevrolet Volt batteries. It is likely more and more car manufacturers will adopt this strategy in the next few years as the first generation of EV batteries become obsolete for use in transportation applications.'

Source: VSA Capital Battery Supply Chain Report [7th Jan 2016]

Nissan has made a big environmental push, turning to renewable energy at its Sunderland plant and investigating ways to repurpose used EV batteries. Here Leaf batteries are supplying power to a data centre in France. According to Nissan, between 1.5 and 2 percent of the world's electricity is consumed by data centers. That's a percentage that rises every year, too. Unfortunately, it's not easy to run a stable data center on renewable energy, because they're incredibly sensitive to outages. [Source: NewAtlas.com ]

*

FLOW BATTERIES

'Flow batteries store energy in an electrolyte held in two external tanks. These liquids are pumped through the battery, where each comes into contact with an electrode. Imergy and CCE use Vanadium redox technology, whilst Primus and RFX favour a zinc-bromide formula in their batteries.

'It is widely believed that flow batteries are the most effective for industrial scale storage. Firstly, they have an extensive storage life and require little maintenance, which makes their levelised cost of energy cheaper than lithium-ion batteries. Secondly, they can be easily scaled up in the amount of energy needed stored, simply by increasing the size of the electrolyte tank.

'However, due to the fact that lithium-ion batteries are much further ahead than flow batteries in terms of development and commercialisation, it might mean that companies looking for commercial storage in the near future could use Li-batteries which when stacked together can store energy on a large scale.'

Source: VSA Capital Battery Supply Chain Report [7th Jan 2016]

A new flow battery that uses lithium ion technology is able to hold more energy in a given volume than those already on the market.

'Industrial-scale batteries, known as flow batteries, could one day usher in widespread use of renewable energy—but only if the devices can store large amounts of energy cheaply and feed it to the grid when the sun isn’t shining and the winds are calm. That’s something conventional flow batteries can’t do. Now, researchers report that they’ve created a novel type of flow battery that uses lithium ion technology—the sort used to power laptops—to store about 10 times as much energy as the most common flow batteries on the market. With a few improvements, the new batteries could make a major impact on the way we store and deliver energy.

Flow batteries aren’t much different from the rechargeables we’re all used to, aside from their massive size....But in flow batteries, the charges are stored in liquid electrolytes that sit in external tanks... Because those tanks have no size limit, the storage capacity of a flow battery can be scaled up as needed. That makes them ideal for storing large amounts of power for the grid.

Today, the most advanced flow batteries are known as vanadium redox batteries (VRBs), which store charges in electrolytes that contain vanadium ions dissolved in a water-based solution...

Lithium ion batteries have a far higher energy density than VRBs. But it’s been difficult to incorporate their technology into flow batteries.... To address this problem, researchers led by Qing Wang, a materials scientist at the National University of Singapore, came up with a bit of a hybrid solution.

'It’s “very innovative” work, says Michael Aziz, a flow battery expert at Harvard University. But he adds that even though the novel battery has a high energy density, the rate at which it delivers that power is 10,000 times slower than conventional flow batteries, far too slow for most applications.

[If they can improve the speed], the new lithium flow batteries could give a much-needed jolt to renewable power storage.'

By Robert F. Service [Science/Nov. 27, 2015]

*

IRENA ROAD MAP

Roadmap Breaks New Ground on Renewable Energy Storage

[International Renewable Energy Association (IRENA)/9 Jun 2015]

To avoid the worst effects of climate change and accelerate sustainable energy transformation and economic growth, IRENA’s REmap 2030 report finds the share of renewables in the electricity sector must double to 45 per cent by 2030. To do so, an estimated 150 GW of battery storage and 325 GW of pumped-storage hydroelectricity will be needed, making storage a vital element in the expansion of renewable energy.

The five priority areas identified include electricity storage to support renewables in islands and remote areas, consumer-located storage for self-consumption in countries with high shares of rooftop solar PV systems, generator and grid-located storage for countries with grid infrastructure constraints and system analysis tools for countries preparing to transition their power sector towards renewables. Download the full report as pdf here;

*

THE EV REVOLUTION

Global EV sales have increased by at least 50% year-on-year (YoY) for the last three years. In the first 11 months of 2015 there were global sales of 446,821. EV sales make up less than 0.1% of global vehicle sales. Even if there is significant growth in key markets in the next few years they will still fail to make an impact on the global vehicle market However it's clear that in the longer term there is an immense market opportunity.

One of the main factors that is slowing take-up is the high cost/ of batteries which make up approximately 25% of the overall cost. There is a decline in the cost of Lithium-Ion batteries but to make EVs competitive with regular fuel cars, cost will have to drop to US$230 per kWh; to achieve mainstream market penetration costs will have to fall to US$150 per kWh

China and US are the top two largest EV markets making for 50% of all EVs sold in 2015

China is one of the largest car markets in the world and has more than 150m cars on the road.

There is a pressing need to reduce emission in Chinese cities and the government provides financial incentives to encourage EV use. The market has seen +155%YoY growth. China is invesiting US$16bn in building a national network of charging docks which are compatible for all EVs except Tesla cars. In 2013 it had roughly only 400 charging stations at a time when the USA had 20,000).

European sales of 151,45l in the first 11 months of 2015 was an+ 80% YoY increase. The most growth was in the UK (25,096/+102%YoY) and France (23,682/+70%YoY).

Infrastructure investment in UK has seen a growth in charging points -from a few hundred in 2011 to more than 9,000 (Sept 2015). The UK government were planning to invest £43m in EV development but whether that has survived the turmoil of Brexit..?

France provides generous government subsidies and sales were helped by the realease of a Renault EV. The most popular EVs in Europe are the Mitsubishi Outlander and Nissan Leaf. All countries in the EU have signed up to an infrastructure target of one charging point for every 10 EVs on road by 2020 - all built to common standards so trans-European travel is possible.

EVs used to be a niche manufacturing industry. Now models are being released by every major car manufacturer. Three models account for 40% of global EV sale in 2014: the Nissan Leaf (61,000 globally), the Mitsubishi Outlander (31,000) and the Tesla 5 (31,000) . [Will find more recent figures]

One of the main factors that is slowing take-up is the high cost/ of batteries which make up approximately 25% of the overall cost. There is a decline in the cost of Lithium-Ion batteries but to make EVs competitive with regular fuel cars, cost will have to drop to US$230 per kWh; to achieve mainstream market penetration costs will have to fall to US$150 per kWh

China and US are the top two largest EV markets making for 50% of all EVs sold in 2015

China is one of the largest car markets in the world and has more than 150m cars on the road.

There is a pressing need to reduce emission in Chinese cities and the government provides financial incentives to encourage EV use. The market has seen +155%YoY growth. China is invesiting US$16bn in building a national network of charging docks which are compatible for all EVs except Tesla cars. In 2013 it had roughly only 400 charging stations at a time when the USA had 20,000).

US: car market boomed as a whole in 2015, shifting 17.4m units but sales of EVs stuttered. Low petrol prices removed incentives. Many people were holding off purchasing current EVs as they waited for the next more technologically advanced models. The most popular EVs are the Tesla Model 5, Nissan Leaf and Chevrolet Vol in that order. The last two, launched second-generation versions in 2016. A new Tesla EV costing $35, 000 and aimed at mass market is to be launched in 2017.

Norway is the third largest market for EV sales and the third largest seller, despite only having a population of five million. One in five new cars now sold in the country is an EV. Norway will likely be the first country to fully embrace mass adoption of EVs. An inherently environmentally conscious country with the highest fuel taxation in the world, the government has incentivised EV use. EVs can drive in bus lanes and can be parked for free. There is also no purchase or VAT tax providing £5,000 a year savings for each driver.European sales of 151,45l in the first 11 months of 2015 was an+ 80% YoY increase. The most growth was in the UK (25,096/+102%YoY) and France (23,682/+70%YoY).

Infrastructure investment in UK has seen a growth in charging points -from a few hundred in 2011 to more than 9,000 (Sept 2015). The UK government were planning to invest £43m in EV development but whether that has survived the turmoil of Brexit..?

France provides generous government subsidies and sales were helped by the realease of a Renault EV. The most popular EVs in Europe are the Mitsubishi Outlander and Nissan Leaf. All countries in the EU have signed up to an infrastructure target of one charging point for every 10 EVs on road by 2020 - all built to common standards so trans-European travel is possible.

EVs used to be a niche manufacturing industry. Now models are being released by every major car manufacturer. Three models account for 40% of global EV sale in 2014: the Nissan Leaf (61,000 globally), the Mitsubishi Outlander (31,000) and the Tesla 5 (31,000) . [Will find more recent figures]

Battery Supply Chain Report produced by VSA capital [7th Jan 2016]

Breakthrough battery tech could make electric cars more efficient

By BEN WOODS/25 July 2016/Wired

'Researchers have proposed a new lithium-oxygen battery technology that could make long-distance electric cars (and smartphones that don't need recharging every day) a reality.

Lithium-air or lithium-oxygen batteries hold the potential for between 5-15 times the efficiency of existing lithium-ion batteries for electric cars, but have seen a number of technological challenges hindering progress - primarily that nearly a third of the energy is still being wasted as heat, and they don't tend to last very long.

Ju Li, professor of nuclear science and engineering at the Battelle Energy Alliance and MIT, led the study, along with Zhi Zhu and five other researchers from MIT, Argonne National Laboratory and Peking University.

The new approach, outlined in the journal Nature, results in a 'nanolithia cathode' battery, which is more versatile and side-steps a few of the key issues with Lithium-oxygen batteries, such as needing other systems to keep away carbon dioxide and water.'

*

New facility could almost double the world's production of lithium ion batteries and reduce Tesla's battery costs by more than a third by 2018

Madeleine Cuff. 27 July 2016

www.businessgreen.com

Tesla yesterday opened the doors to its Gigafactory, the $5bn lithium ion battery factory in Nevada, US, that will support a massive increase in the company's production of electric cars. The site is only 14 per cent completed, but once fully operational the factory is expected to almost double the world's production of lithium ion batteries, and at 10 million square feet will be one of the largest buildings in the world.

New facility could almost double the world's production of lithium ion batteries and reduce Tesla's battery costs by more than a third by 2018

Madeleine Cuff. 27 July 2016

www.businessgreen.com

Tesla yesterday opened the doors to its Gigafactory, the $5bn lithium ion battery factory in Nevada, US, that will support a massive increase in the company's production of electric cars. The site is only 14 per cent completed, but once fully operational the factory is expected to almost double the world's production of lithium ion batteries, and at 10 million square feet will be one of the largest buildings in the world.

Tesla founder Elon Musk said the Gigafactory will start production of batteries by the end of this year, and gradually ramp up manufacturing as more of the site is completed until it is delivering 35 gigawatt hours of batteries by 2018 - enough to support about 1.5 million cars a year.

The Gigafactory's size - and production capabilities - will be around three times larger than the original plans for the site. When work began on the factory in 2014, it was thought the site would produce enough batteries for around 500,000 Tesla cars by 2020.

The batteries will be used in the production of Tesla's latest EV, the Model 3, which attracted more than 325,000 pre-orders in a matter of weeks. The car is Tesla's first mass market vehicle, with an initial price tag of $35,000.

The factory will also support the expansion of Tesla's Powerwall business, which provides stationary battery storage to homes and businesses. Musk told reporters "The growth in stationary storage is really under-appreciated," he said. "That is a super-exponential growth rate."

HYDROGEN FUEL CELL VEHICLES

|

| Source: The Earth Project |

At present, EV's and their charging point infrastructure are significantly more developed. In the

UK for instance, there are 9,300 EV charging points ad only 4 hydrogen filling stations.

EVs are cheaper and have similar bodies to conventional cars. Fuel cell vehicles are considerably heavier and larger to accommodate the fuel cell.

There is probably a place for both on the market as long as price of fuel cell falls.

Source: VSA Capital Battery Supply Chain Report [7th Jan 2016]

by Cara McGoogan [Telegraph/12th Sept 2016]

Code-named project Titan, Apple has plowed resources into a mysterious department looking at electric vehicles and self-driving car technology for at least two years to no avail, the New York Times reports.

Despite numerous high profile hires and Tim Cook's suggestion that the car industry should expect "massive change", Apple has closed sections of the project and laid off staff in a move that could signal it is abandoning plans to create its own car.

The news follows the appointment of Apple veteran Bob Mansfield as head of the project in July. Mansfield has decided to double down on efforts to created self-driving technology rather than making an electric vehicle itself, according to the Financial TimeS.

*

No comments:

Post a Comment